Why Nickel Alloy 200 Is a Go-To Choice for Corrosion Resistance

In industries where equipment is frequently exposed to harsh chemicals, moisture, or high temperatures, corrosion can slowly erode the integrity of the system while not being noticed. Corroded systems will inevitably incapacitate If your material fails due to corrosion, the result will be leaks, failures, and expensive downtime.

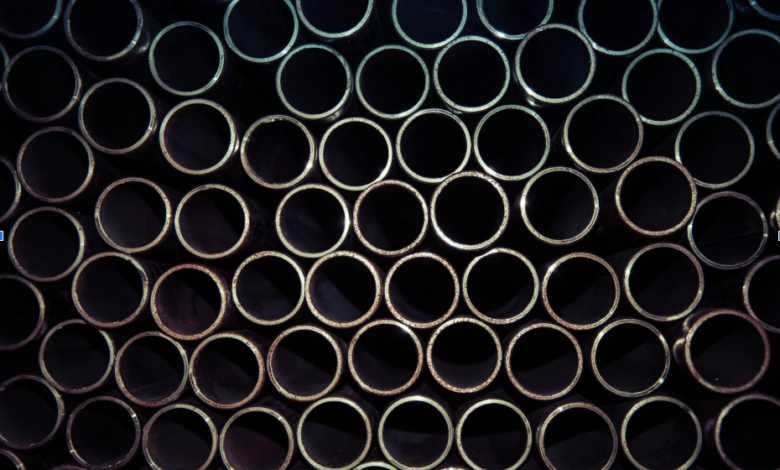

Choosing the right material, like the Nickel alloy 200 tubing, to begin with is imperative in this case as well as in the operation of tubing and piping used in industrial process.

Nickel Alloy 200 is one of many alloys that may offer value to industry and all of its’ applications due to its resistance to corrosion. Users include chemical processing, aerospace, power, and marine with long term usage objectives. Not to mention, it is an effective value in comparison to most exotic alloys that have much higher cost and processing concerns, Nickel Alloy 200 tubing balances strength, workability, and corrosion resistance.

What Is Nickel Alloy 200?

Nickel Alloy 200 is commercially pure wrought Nickel which is known for its mechanical properties, as well as its resistance to corrosive environments. It is over 99% Nickel which greatly assist in the alloys’ corrosion and thermal protection. When constructed specially for tubing, Alloy 200 is found in multiple constructions such as seamless, welded, or drawn tubing. This gives the tubing construction alternative to serve multiple users within industry that require material to be constructed to operate in very chemically aggressive and/or very high temperature atmospheres.

Why Corrosion Resistance Matters

Corrosion can affect both the surface and internal structure of metals, leading to reduced lifespan, safety risks, and increased maintenance costs. Nickel Alloy 200 resists many common forms of corrosion, including:

- Atmospheric corrosion

- Alkaline solutions

- Neutral and mildly reducing environments

This resistance is a major reason why it’s often used in chemical processing systems, marine applications, and environments where moisture or salt exposure is common. The alloy forms a passive oxide layer that protects the metal underneath, ensuring it does not degrade easily over time.

High Performance in Heat and Stress

Aside from resisting chemical attack, Nickel Alloy 200 also performs well under high temperatures. Its ability to retain mechanical strength in elevated thermal conditions makes it a trusted material in power plants, heat exchangers, and aerospace components. Unlike many other metals that lose tensile strength or become brittle under constant heat, this alloy maintains its structure. It also offers excellent stress rupture and creep resistance, which are important when designing components that will endure long-term mechanical load at high temperatures.

Fabrication and Tubing Flexibility

Nickel Alloy 200 can be fabricated into various tubing forms depending on the requirements of the application. Seamless tubes offer a smooth interior for fluid flow, while welded tubes are often used when cost or availability is a factor. Drawn tubing provides tighter dimensional tolerances and better surface finishes. Its good ductility and weldability allow it to be processed without compromising its properties. This means engineers can bend, cut, and install it into custom assemblies without worrying about weakening the metal’s performance.

A Look at Real-World Applications

Because of its resilience in corrosive and high-temperature environments, Nickel Alloy 200 tubing finds use in several sectors:

- Chemical handling and processing lines

- Food processing equipment (due to its purity)

- Marine and seawater systems

- Power generation plants

- Aerospace fuel and hydraulic lines

Each of these settings presents unique challenges—whether it’s exposure to alkalis, saltwater, or fluctuating heat. Nickel Alloy 200 is often chosen in these environments because of its reliable, long-term behavior.

See also: Creating Test Cases for Successful Cross-Browser Evaluation

Comparison with Other Nickel Alloys

Nickel Alloy 200 is not the only nickel-based material on the market. However, it holds a unique place among its peers. For example, Nickel Alloy 400 has higher strength and performs better in certain acidic conditions. But it’s more complex and costly. In contrast, Nickel Alloy 200 offers predictable behavior in general-use applications without unnecessary alloying elements. This makes it easier to machine, weld, and integrate into systems that don’t require extreme corrosion protection.

When ultra-high corrosion resistance is needed—such as against strong oxidizing acids—engineers may opt for Alloy 600 or 625. But for mild to moderate environments, Alloy 200 is often sufficient and more cost-effective.

Strengths You Can Rely On

Nickel Alloy 200 is known for its consistent performance. Some of its most valuable properties include:

- Corrosion resistance in neutral and alkaline conditions

- High thermal and electrical conductivity

- Low gas content and vapor pressure (ideal for electronics and aerospace)

- Strong mechanical properties at both room and elevated temperatures

These features ensure the alloy remains a go-to option for both critical infrastructure and day-to-day industrial setups.

Practical Tips and Considerations

Even with its many advantages, it’s important to consider whether Nickel Alloy 200 is appropriate for your specific application. While it performs well in most environments, it is not ideal for highly oxidizing or strongly acidic conditions. In such cases, switching to more specialized alloys may be necessary.

Proper fabrication practices should also be followed to preserve its corrosion resistance. Avoiding contamination, using appropriate welding methods, and following standard installation protocols can help extend the alloy’s service life.

A Material Built for the Long Run

The long-term cost of corrosion and system failure can be immense. That’s why materials like Nickel Alloy 200 continue to be used in mission-critical systems. Its simplicity, paired with dependable corrosion resistance and mechanical performance, makes it suitable for long-term use in pipes, heat exchangers, and chemical transport lines. Its widespread availability in standard tubing sizes, coupled with its processability, ensures that manufacturers and designers can count on it when working on time-sensitive or technically demanding projects.

Conclusion

Nickel Alloy 200 is more than just a corrosion-resistant material, it is a well-rounded solution for various industrial challenges. From chemical plants to marine systems and power stations, it provides the durability and stability that engineers seek when performance cannot be compromised. With a combination of corrosion resistance, heat tolerance, mechanical strength, and flexibility in fabrication, it continues to be a reliable choice in modern industrial design. For any application where environmental exposure is a concern, Nickel Alloy 200 tubing is a material worth serious consideration.